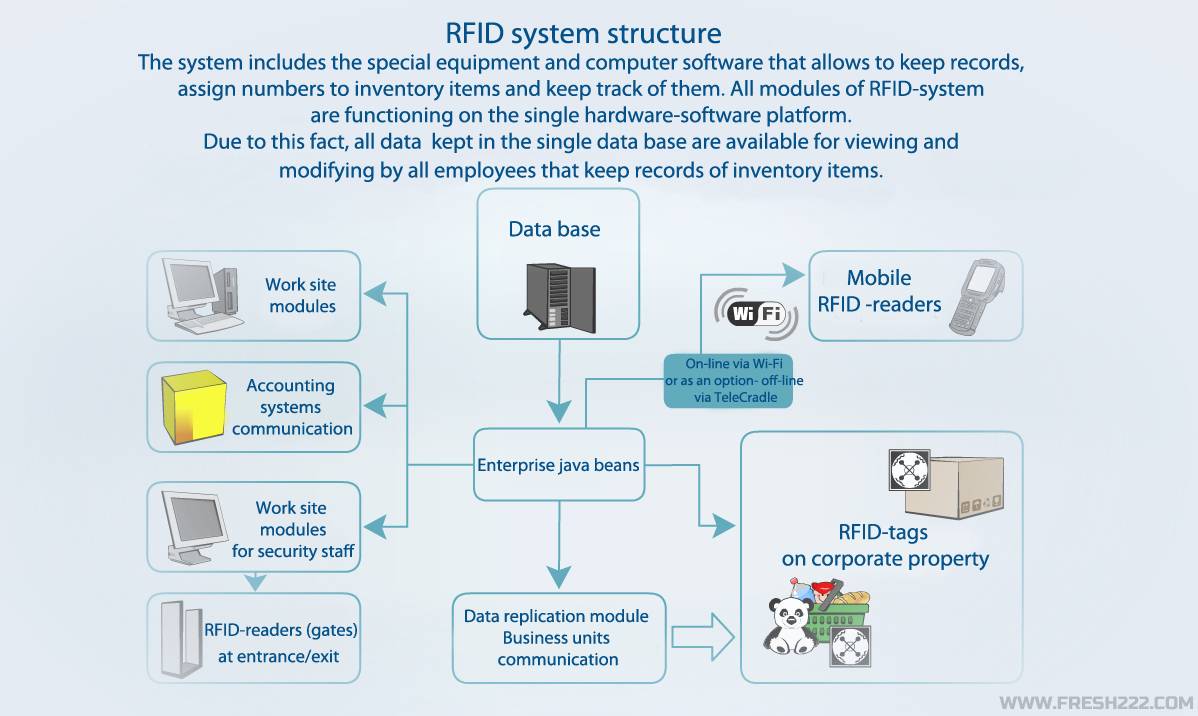

To get a demo version of the software for sorting on conveyors and a description of the systems, please contact us with an email request. The RFID sorting system is the most advanced sorting system for conveyors with the ability to track each unit and integrate with any ERP enterprise system.

Sorting Conveyor

Sorting Conveyor System - a high-tech solution for sorting on conveyors from Fresh USA is the quick recognition of goods by RFID UHF tags, high-speed sorting, as well as quick inventory and safe distribution of stocks.

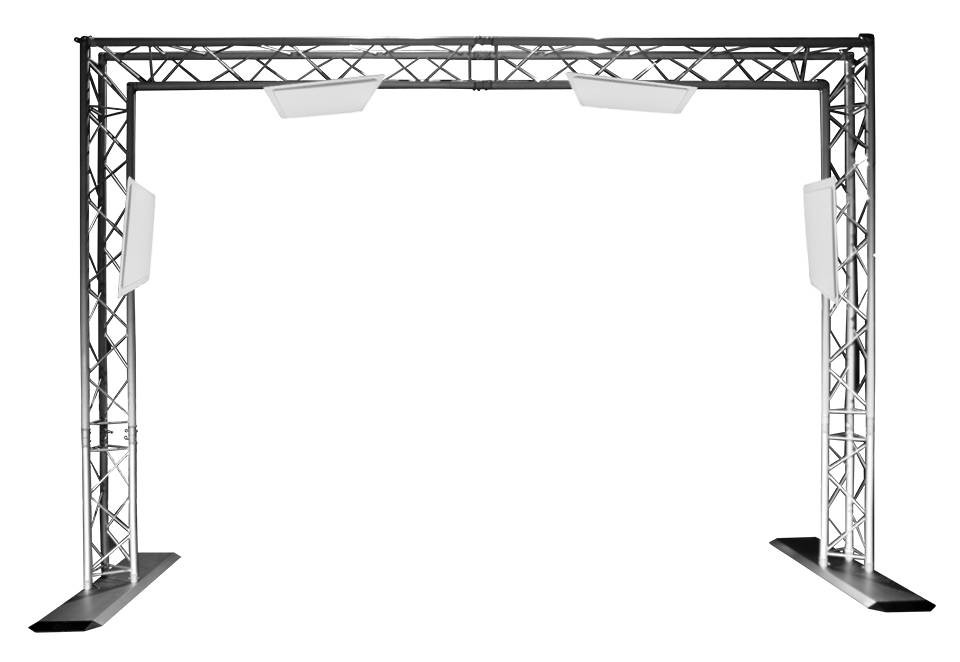

Everything works very simply, the reader at an adjusted distance recognizes the object by the RFID tag and sends a signal to the diverter, which distributes the object in the desired direction. An unlimited number of products and destinations intended for them can be stored in the database.

RFID readers and RFID tags for inventory and sorting on conveyor systems.

Using our RFID sorting system, you can automatically distribute goods across multiple groups. The system has an additional option – fast RFID inventory.

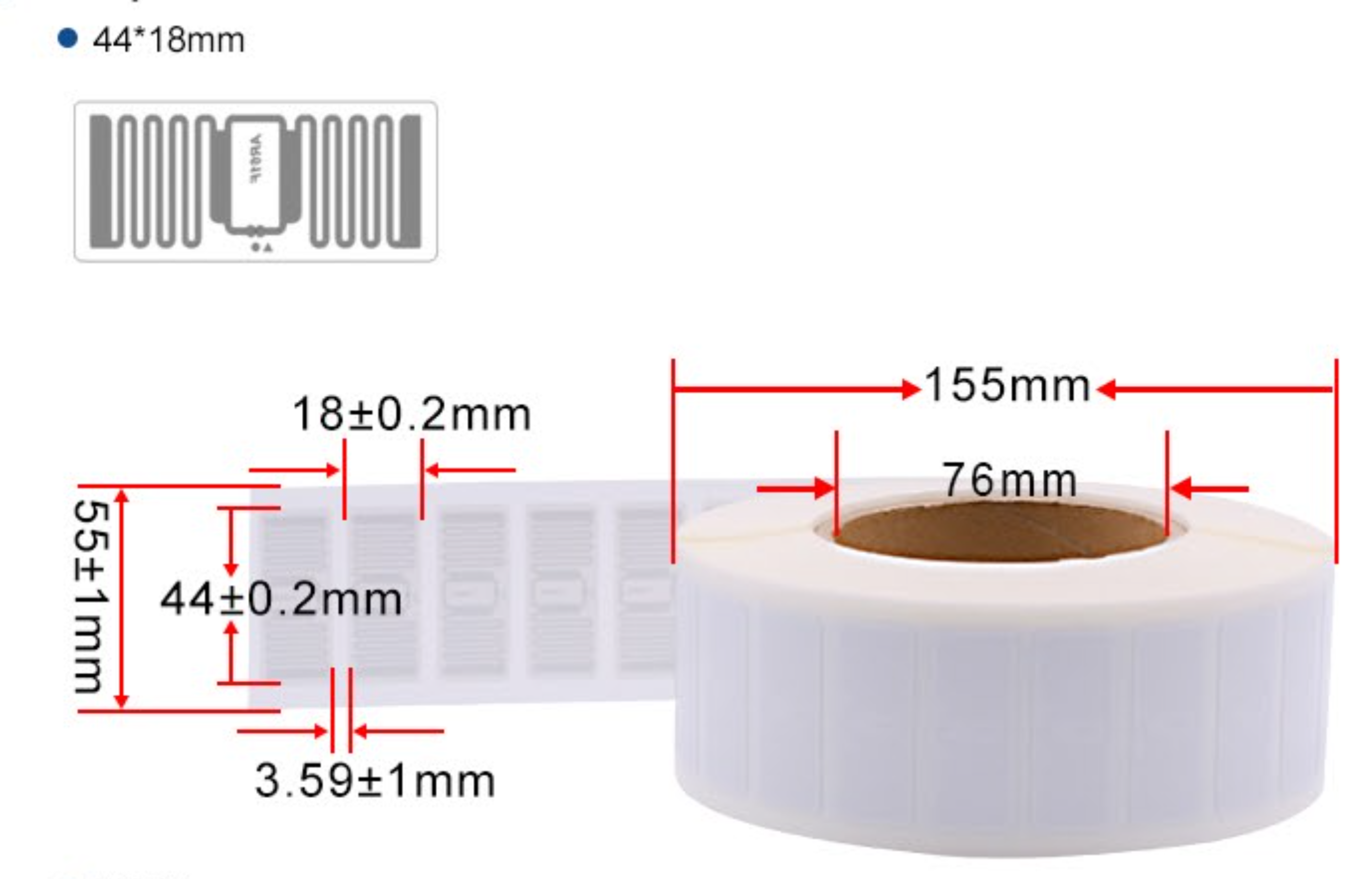

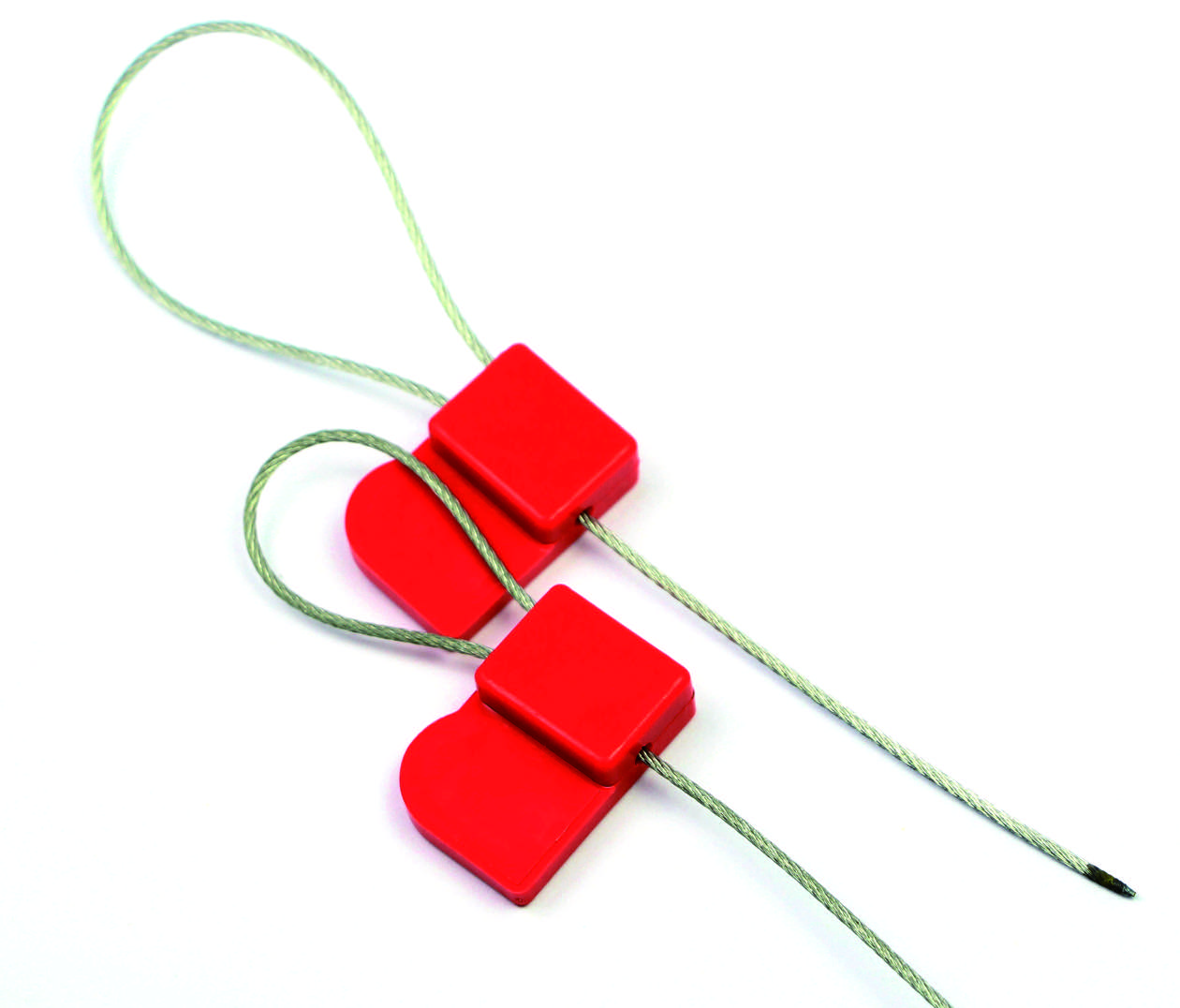

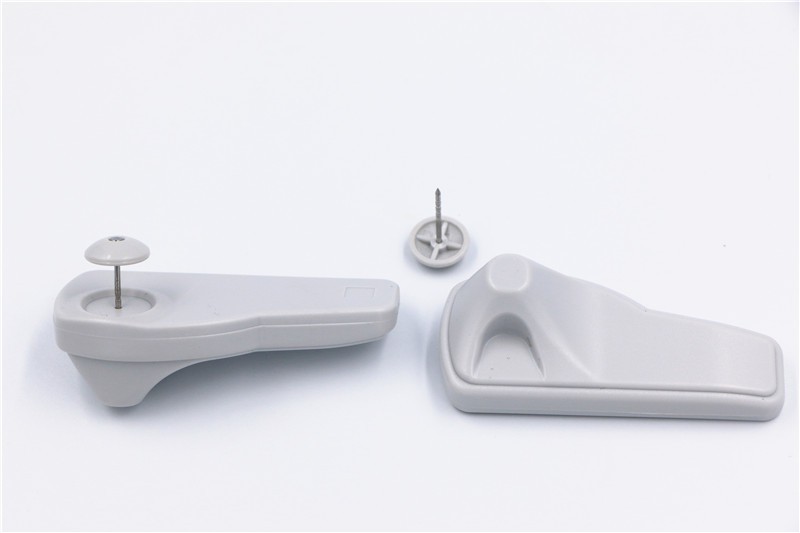

Application example for sorting conveyor system RFID UHF Tags of different types.

- Tag Specifications suitable for this anti-theft system DOWNLOAD here: PDF

- Anti-metal Industrial Tags specification DOWNLOAD here: PDF

Enhancing Conveyor and Sortation Equipment Efficiency with RFID Technology

Introduction

In today’s fast-paced and competitive business landscape, optimizing operational efficiency and streamlining processes are paramount for organizations across various industries. One area where significant gains can be achieved is in the realm of conveyors and sortation equipment. By leveraging advanced technologies such as Radio Frequency Identification (RFID), businesses can unlock new levels of automation, accuracy, and productivity. In this article, we explore the powerful impact of RFID technology on conveyors and sortation systems, showcasing how it revolutionizes supply chain management and enhances overall operational performance.

Streamlining Operations with RFID-enabled Conveyors

1. Real-time Item Tracking and Inventory Management

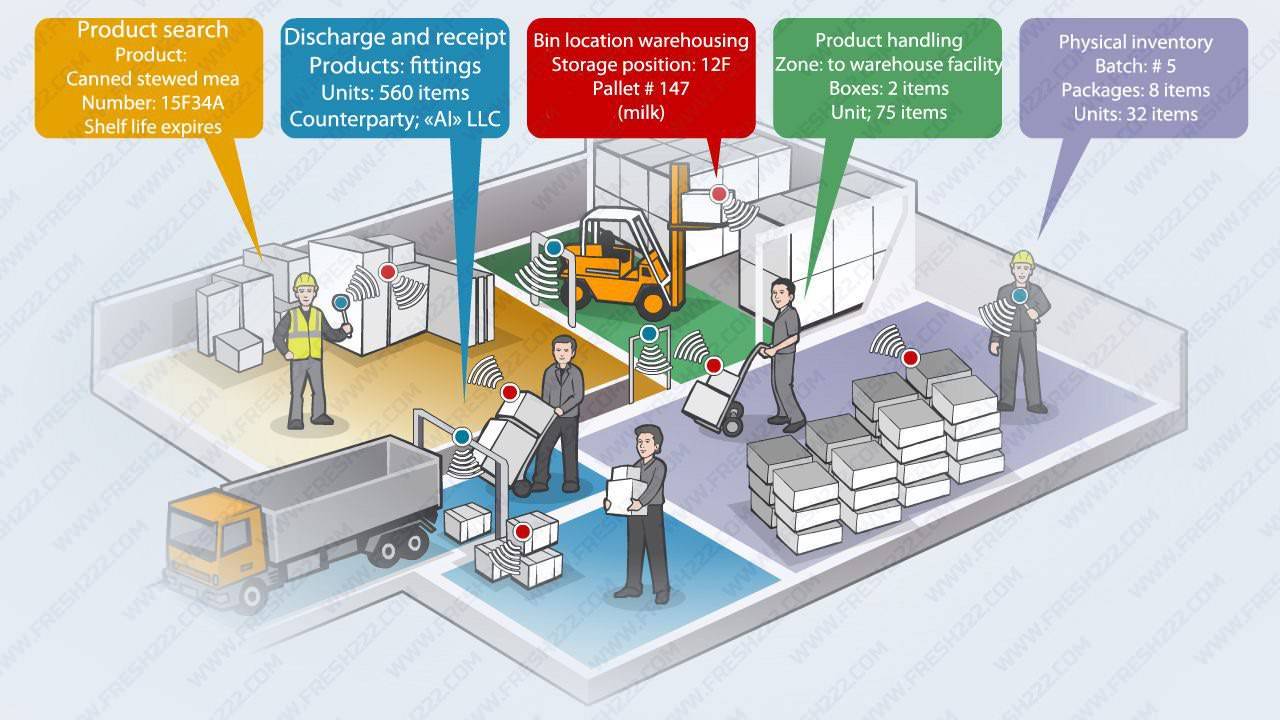

With RFID technology integrated into conveyors and sortation equipment, businesses gain unparalleled visibility into their supply chain. RFID tags, consisting of microchips and antennas, are affixed to individual items or packaging units, allowing for seamless identification and tracking throughout the entire conveyor system. By capturing real-time data on item location, movement, and quantity, businesses can optimize inventory management, reduce stockouts, and enhance order fulfillment processes. This level of precision enables companies to maintain accurate stock levels, prevent costly delays, and ensure customer satisfaction.

2. Automated Sorting and Routing

Conveyors equipped with RFID technology can significantly enhance sorting and routing capabilities. As items pass through the conveyor system, RFID readers strategically positioned at various points capture tag information, enabling automatic identification and sorting based on predefined criteria. This automation eliminates the need for manual intervention, reducing human error and expediting the sorting process. By leveraging RFID technology, businesses can achieve higher throughput rates, decrease processing times, and enhance overall productivity.

3. Error Reduction and Quality Control

The integration of RFID technology into conveyors also serves as a powerful tool for error reduction and quality control. RFID tags can store detailed information about individual items, including manufacturing data, expiration dates, or quality specifications. By continuously monitoring this information during the conveyor journey, businesses can identify and address potential issues or anomalies in real-time. This proactive approach minimizes errors, reduces waste, and ensures that only high-quality products reach customers, bolstering brand reputation and customer loyalty.

Benefits of RFID-enabled Conveyors and Sortation Systems

1. Increased Efficiency and Productivity

By harnessing the capabilities of RFID technology, conveyors and sortation systems become integral components of highly efficient and productive supply chains. The automation provided by RFID-enabled equipment eliminates time-consuming manual tasks, reduces labor costs, and optimizes throughput rates. With streamlined operations, businesses can handle larger volumes of items with greater speed and accuracy, leading to improved productivity and cost savings.

2. Enhanced Visibility and Traceability

RFID technology offers unparalleled visibility and traceability throughout the supply chain. Each item’s unique RFID tag allows businesses to precisely track its journey from manufacturing to delivery. This comprehensive visibility enables effective inventory management, proactive maintenance, and rapid response to potential bottlenecks or delays. Additionally, RFID technology facilitates compliance with regulatory requirements and industry standards, providing organizations with the necessary tools to meet auditing and reporting obligations.

3. Seamless Integration with Existing Systems

One of the significant advantages of RFID-enabled conveyors and sortation systems is their compatibility with existing infrastructure. The technology can be seamlessly integrated with warehouse management systems (WMS), enterprise resource planning (ERP) software, and other data management platforms. This integration ensures that real-time RFID data is effortlessly synchronized with relevant systems, empowering businesses with accurate and up-to-date information for decision-making and process optimization.

Conclusion

In today’s highly competitive business environment, leveraging advanced technologies to gain a competitive edge is essential. RFID-enabled conveyors and sortation equipment represent a transformative solution that revolutionizes supply chain management. By harnessing the power of RFID technology, businesses can achieve heightened efficiency, streamlined operations, and improved overall performance. From real-time item tracking and inventory management to automated sorting and quality control, the benefits of RFID integration are vast. Embracing RFID-enabled conveyors is a strategic move that allows businesses to enhance productivity, reduce errors, and optimize their supply chain for sustained success in the digital era.

Hardware for Sorting Conveyors.

Handheld mobile RFID Inventory reader F-880 (mobile terminal for data collection) the price $ 1,250 including software that is integrated with EPC

|

RFID portable hand-held reader F-880 |

|

| Operating frequency | UHF 860-960 MHz |

| Protocol | ISO18000-6C, EPC Class 1 Gen 2, ISO18000-6B |

| Reading distance | 200-1300 cm |

| RSSI | Indicator of received signal |

| Discrepancy prevention | Reading up to 400 tags at a time |

| Antenna polarization | Circular polarization |

| SDK | Free SDK conditions applied to a reader |

|

System possibilities |

|

| Operation system | Microsoft® Windows CE® 6.0 или Android OS v2.2 |

| Processor | SAMSUNG Cortex-A8(1GHz) |

|

Memory |

|

| Memory | 256MB/512MB Mobile DDR RAM |

| Flash-memory | 256MB/512MB Nand Flash ROM |

| Additional inline memory | Micro SD 32G (Maximum) |

|

Audio, slots, ports |

|

| USB ports | yes |

| Slots | 1 MicroSD Slot, 1 GSM/GPRS Slot |

| Camera | It extends |

| 1D bar-code | available |

| 2D bar-code | It extends |

|

Input/output device |

|

| Input device | QWERTY keyboard, touch-screen in colour, stilos, start button, upper-case input support |

| Output device | 3.5” Transmitting LCD, QVGA(240 x 320) or VGA(480 x 640), LED x 2, zoomer (sound buzzer) |

|

Communication functions |

|

| Wi-Fi | 802.11b/g |

| GPRS (GSM) | GSM/GPRS/EDGE: 850/900/1800/1900MHz |

| 3G | WCDMA / CDMA2000 |

| Bluetooth | Bluetooth 2.1 + EDR class 2 |

| GPS | integrated |

|

Features |

|

| Dimensions | 190 x 75 x 30 mm |

| Weight | 520 g (with a battery) |

| Case colour | Matted black |

|

Energy features |

|

| Battery | Rechargeable 3.7V 4000mAh battery (accumulator) |

| Power supply | AC Adapter |

|

Use conditions |

|

| International protection | IP65 |

| Operating temperature | -10°C – 50°C |

| Storage temperature | -20°C – 65°C |

| Charge temperature | 0°C – 40°C |

| Moisture content | 5% – 95% without a condensation product |

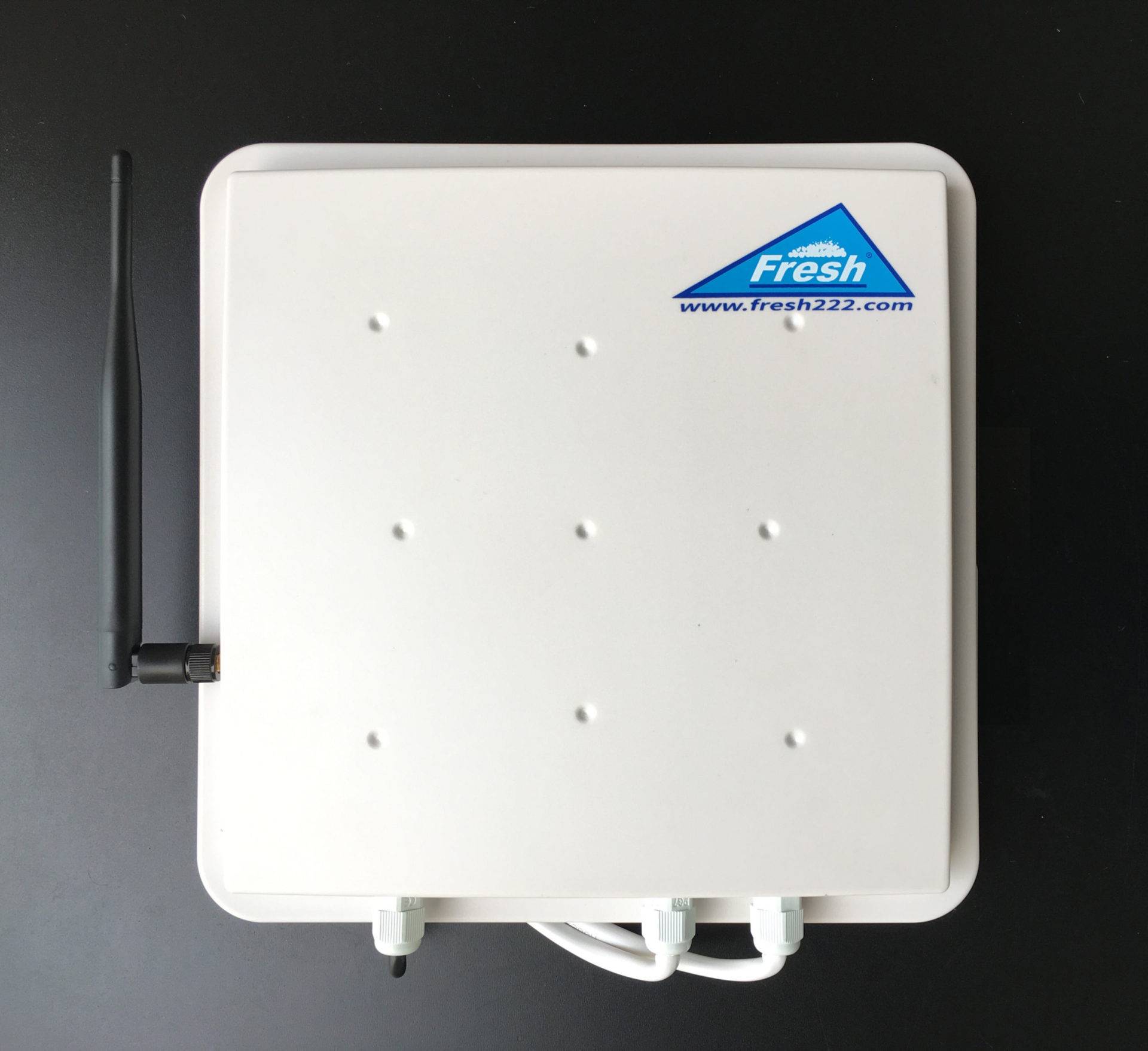

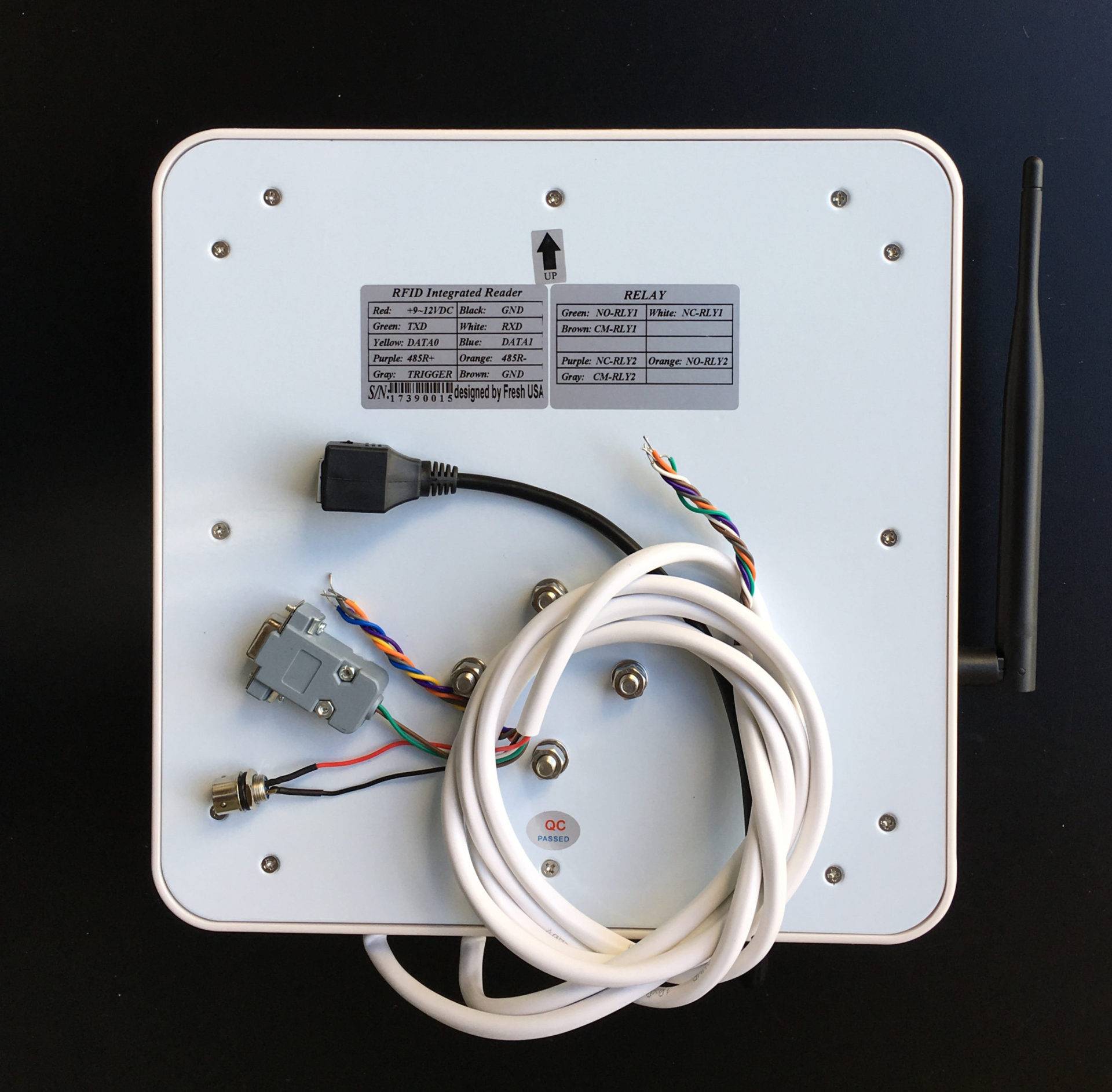

Sorting Conveyor RFID tag reader F-920 (9,8″*9,8″/25*25cm)

|

Features RFID medium range distance tag reader F-920 |

|

| Supporting protocol | ISO18000-6C EPC Gen2 / ISO18000-6B |

| Operating frequency | ISM 902MHz ~ 928MHz, Or 920MHz ~ 925MHz |

| Adjustment frequency | 860MHz ~ 960MHz |

| Operating mode | Operation with a fixed frequency of transmitting pulses that are set by a software |

| Transmitting power | 8 dBm ~ 12 dB (It’s set by a software) |

|

Recording/reading performance |

|

| Reading speed | Average reading speed of one 64-bit card 64 less thanper 10 ms |

| Reading distance | 6m – 8m (It depends on a tag and environment) |

| Speed of recording | 8 bit less thanper 30 ms |

| Writing distance | 2m – 4m (It depends on a tag and environment) |

| Lines reading | Zoomer (signal) |

|

Interface data port |

|

| USB port / WiFi | N/A / Yes |

| RS232 port | Yes |

| RS485 port | Yes |

| Weigand port | Weigand26/34 |

| Trigger port | Yes |

| TCP/IP port (RJ45) | N/A / Yes |

|

Electric parametres |

|

| Power supply | DC+9V,4A |

| Power consumption | 6W |

|

Dimensions and weight |

|

| Dimensions | 9,8″*9,8″ / 250mmх250mmх50mm |

| Weight | 1500 g |

|

Environment operating factors |

|

| Operating temperature | -30°C~70°C |

Fixed RFID tag reader with 4 antenna ports F-6950 for Sorting Conveyor Systems.

|

Name |

Fixed RFID UHF tag reader |

Other models |

| Operation | 3 modes: a proactive mode, answer mode, startup mode | Usually 1 mode, some models can have 2 modes |

| Anti-conflict | Support for labels anti-conflict with excellent effect, the algorithm has no errors | A large number of errors in the algorithm, the instability of the anti-conflict effect |

| Label data storage | Integrated storage system of label data includes port code for the antennas, time, data labels content, etc. | Usually without a storage, it may contain only store data, without other information |

| Label loading data system | Different systems of loading data: manual, time estimate, choice of a certain time, release, addition, modification |

– |

| Label process facilities | Support the reserved area, EPC areas, TID fields, user’s operational areas, it supports complex data masking tape for various fields | Only to achieve EPC area by a direct operation without data masking. Indirectly to finalize TID field |

| Real time | Integrated real-time clock with no data loss when power is off, reading and writing labels has a timestamp. |

– |

| Full labels EAC operation, support the relay link. |

– |

|

| Privacy | Label privacy function is fully supported |

– |

| High speed of data operation | Support for such high-speed data operations as mass flow erase and mass reading, the speed is four times higher. |

– |

| Functional configuration | Without malfunction and supply fail |

– |

RFID UHF tag reader F-930

|

RFID UHF tag reader F-930 (17,7″*17,7″/45*45cm) plus long-range. Features |

|

| Supporting protocol | ISO18000-6CEPC Gen2 / ISO18000-6B |

| Operating frequency | ISM 902MHz ~ 928MHz, Or 920MHz ~ 925MHz |

| Adjustment frequency | 860MHz ~ 960MHz |

| Operating mode | Operation with a fixed frequency of transmitting pulses that are set by a software |

| Transmitting power | 12dBm ~ 30 dBm (set by a software) |

|

Reading/recording performance |

|

| Reading speed | Average reading speed of one 64-bit card 64 less thanper 10 ms |

| Reading distance | 12m -15m (It depends on a tag and environment) |

| Recording speed | 8 bit less thanper 30 ms |

| Recording distance | 4m -7m (It depends on a tag and environment) |

| Lines reading | Zoomer (signal) |

|

Interface data port |

|

| USB port / WiFi | N/A /Yes |

| RS232 port | Yes |

| RS485 port | Yes |

| Weigand port | Weigand 26/34 |

| Trigger port | Yes |

| TCP/IP port (RJ45) | N/A |

|

Electric parametres |

|

| Power supply | DC+9V,4A |

| Power consumption | 6W |

|

Dimensions and weight |

|

| Dimensions | 17,7″*17,7″ / 450mm х 450mm х 60mm |

| Weight | 3700 g |

|

Environment operating conditions |

|

| Operating temperature | -30°C~70°C |