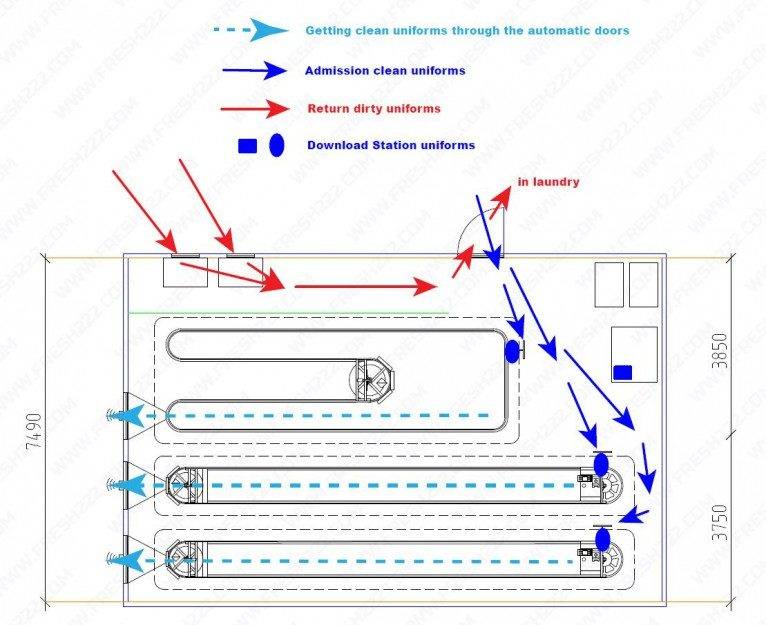

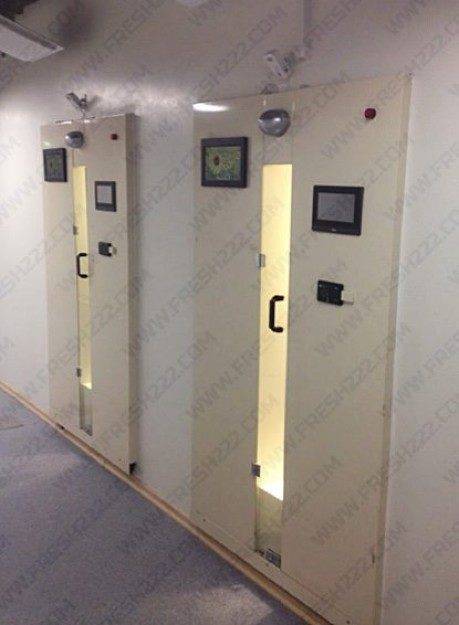

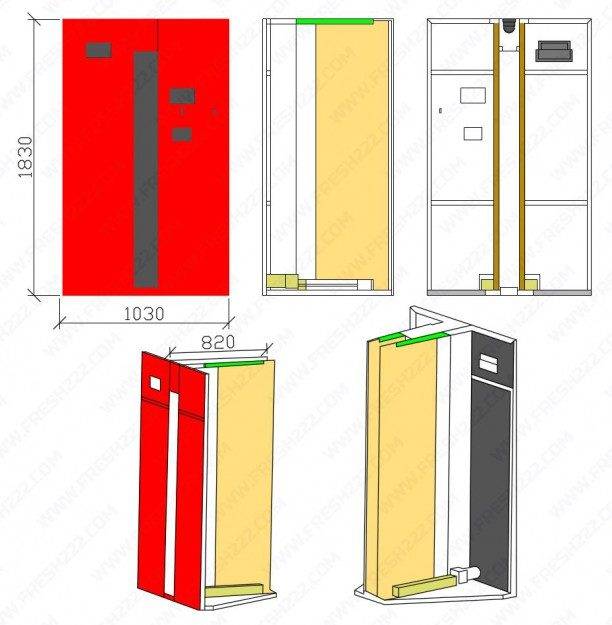

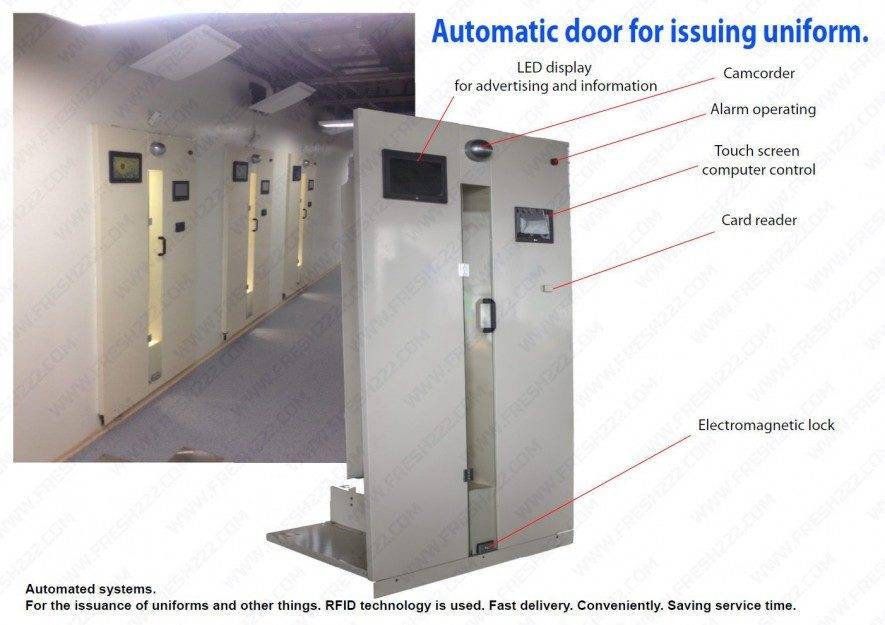

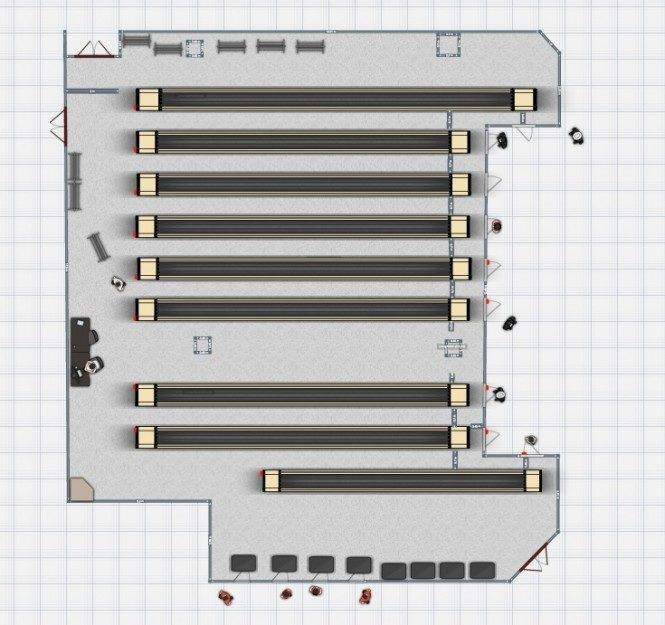

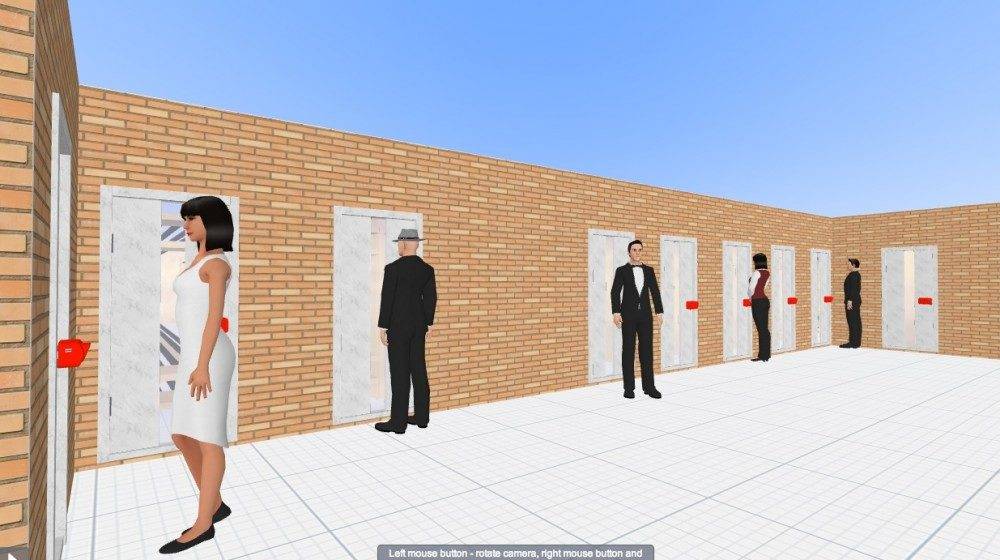

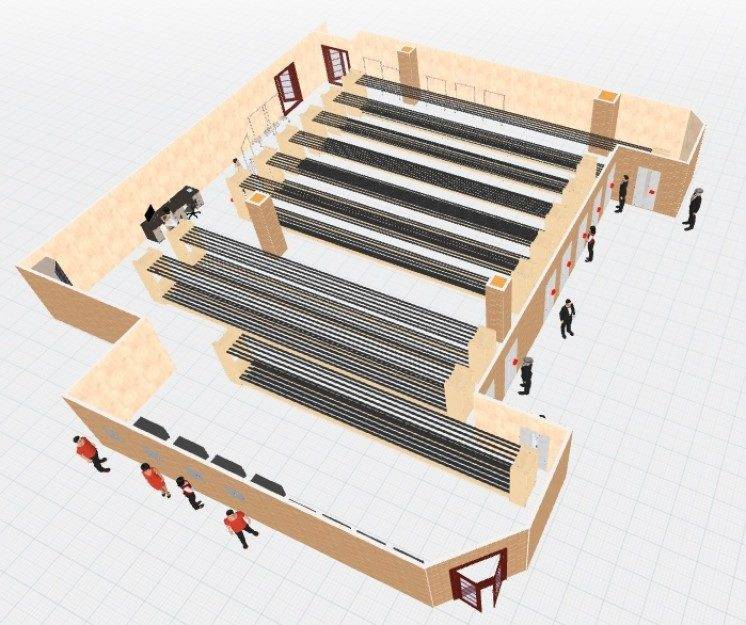

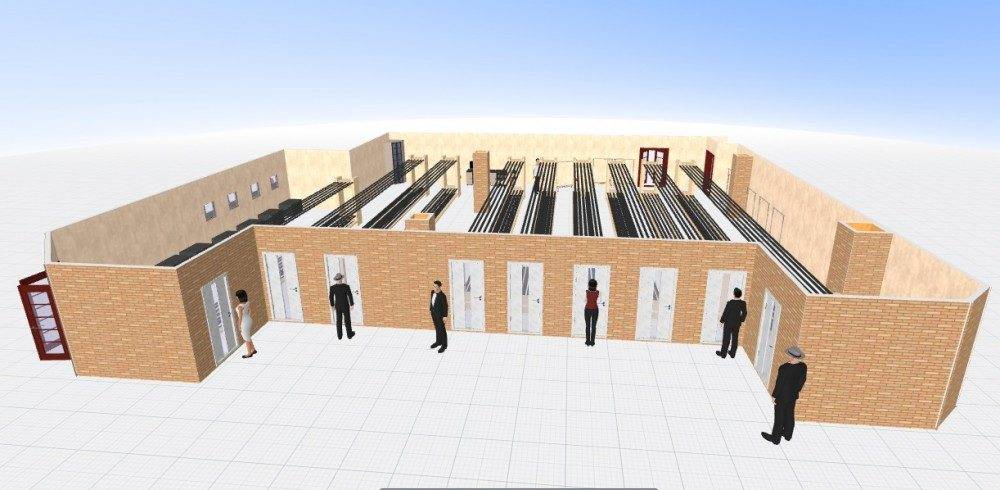

The uniform smart storage system allows to retrieve garments and other items quickly. The user leans a RFID card or a wristband on a reader and gets his uniform set. With a help of software and technologies, the user’s gear is sorted automatically and placed into a correspondent slot on a garment conveyor. It can unite several garments conveyors at a time and several automatic doors for uniform and other garments. Due to special devices in automatic doors, an access is banned to other user’s garments. All this thanks to automated conveyors uniform distribution and RFID technology. The system has a theft protection function. You can also consider the budget solution for storing uniforms, more details here – Uniform Cabinet.

Now we have implemented our newest user face recognition system. Now, the search and issuance of things is done by recognizing the user’s face.

Automatic Uniform Conveyor System is a system for automated uniform storage of search and delivery of uniforms, workwear and other clothes. Our storage systems for uniforms and other clothes have an automatic system for searching and issuing workwear, uniforms and other clothes. Clothing is stored on automatic clothing conveyors. Now we have the most advanced solution during the pandemic and against the spread of other viruses - face recognition. The uniform is issued to a specific employee by the person’s recognized face and identified with his uniform kit. We also offer uniform identification by RFID tags, cards, bracelets and the like!

Аutomated uniform systems for the issuance of uniforms, clothes and other things. Face recognition technology and RFID technology are used.

Face Recognition Access to The Warehouse, Storehouse, Storage, Dressing Room

Automatic uniform storage. Automatic cloakroom.

Benefits of Automated Uniform Storage

Time-Saving Advantages

Uniforms are delivered in seconds, freeing up employees to focus on their work.

Enhanced Security and Theft Prevention

RFID tracking ensures only authorized personnel can access assigned garments, reducing theft and loss.

Cost Efficiency for Businesses

Automation eliminates the need for manual labor, reducing operational costs significantly.

Improved Employee Satisfaction

Employees enjoy hassle-free access to clean, well-maintained uniforms, boosting morale and productivity.

Customization Options for Uniform Storage Systems

Scalable Dimensions for All Spaces

Small-Scale Systems for Compact Spaces

Ideal for businesses with limited storage areas.

Large-Scale Solutions for Big Teams

Perfect for industries managing thousands of uniforms daily.

Integration with Existing Infrastructure

Systems can be seamlessly integrated with your current inventory or HR software.

Specialized Features for Specific Industries

From healthcare scrubs to fire-resistant uniforms, systems can accommodate industry-specific needs.

Applications Across Industries

Healthcare

Effortlessly manage scrubs, lab coats, and other medical garments.

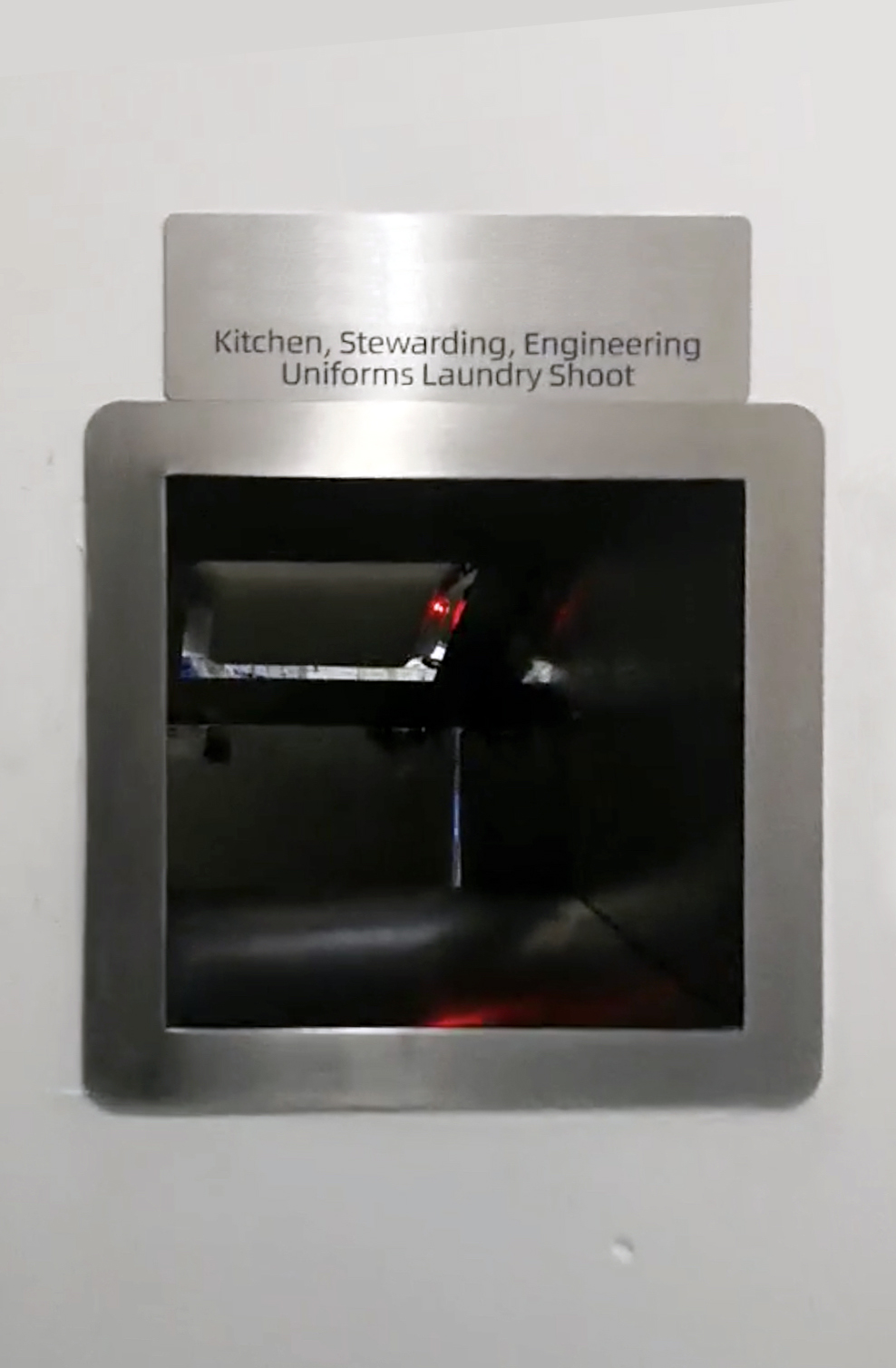

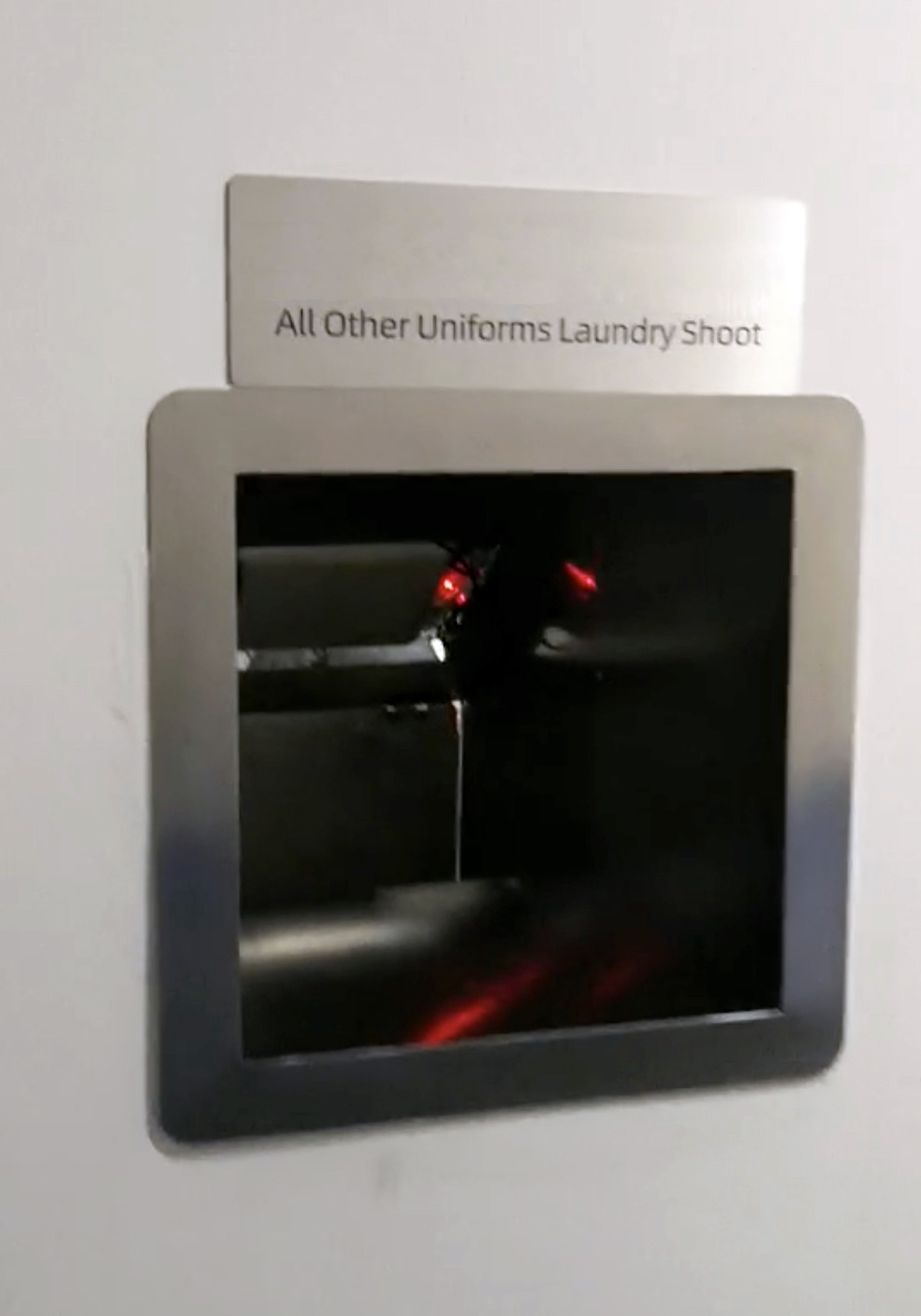

Hospitality

Streamline uniform storage for hotel, restaurant, and event staff.

Manufacturing

Efficiently store protective gear and work uniforms.

Public Services

Secure and organize uniforms for police, fire departments, and emergency responders.

Challenges and Solutions in Implementing Automated Uniform Storage

Initial Cost of Installation

While the upfront cost is high, the long-term savings in labor and uniform loss outweigh the investment.

Adapting to New Technologies

With proper training and support, employees can quickly adapt to using these systems.

Training Staff for Optimal Use

Comprehensive training ensures employees understand and effectively use the system.

Future of Uniform Storage Systems

Emerging Technologies in Automation

AI and IoT integration will further enhance uniform management systems in the coming years.

Sustainability in Uniform Management

Green solutions, such as energy-efficient conveyors, are shaping the future of automated storage.

Conclusion

Automated uniform storage systems are an investment that pays dividends in efficiency, security, and employee satisfaction. With customizable options and cutting-edge technology, they’re the future of uniform management.

FAQs

What is RFID technology in uniform storage systems?

RFID technology uses tags embedded in garments to track and manage uniforms securely and efficiently.

Can automated systems accommodate different garment types?

Yes, systems can store various garments, including specialized uniforms like fire-resistant or medical scrubs.

How long does it take to implement such a system?

Implementation timelines vary, but most systems can be set up within weeks, depending on the scale and customization.

Are these systems secure?

Absolutely. RFID authentication ensures only authorized users can access uniforms, reducing theft and loss.

What industries benefit the most from automated uniform storage?

Healthcare, hospitality, manufacturing, and public services are prime beneficiaries due to their reliance on uniform management.